Nagold. The Boysen Group is investing 40 million Euro in the construction of an innovation and development centre at Nagold in Baden-Württemberg. It will be the exhaust technology specialist's second large development site, joining its headquarters in Altensteig, just 15 kilometres away.

For Boysen CEO Rolf Geisel, the start of the major project is the "last of seven elements of our future and growth strategy, which have been following since the middle of 2012". Five of the other elements are the production plants in Achim near Bremen, Ingolstadt, Tuscaloosa (USA), East London (South Africa) and Langfang (China), which are all set to be completed by 2014. According to Geisel the list is rounded off by the acquisition of MHG Fahrzeugtechnik GmbH from Heubach in Swabia, a specialist in small series and prototype parts for the exhaust sector,

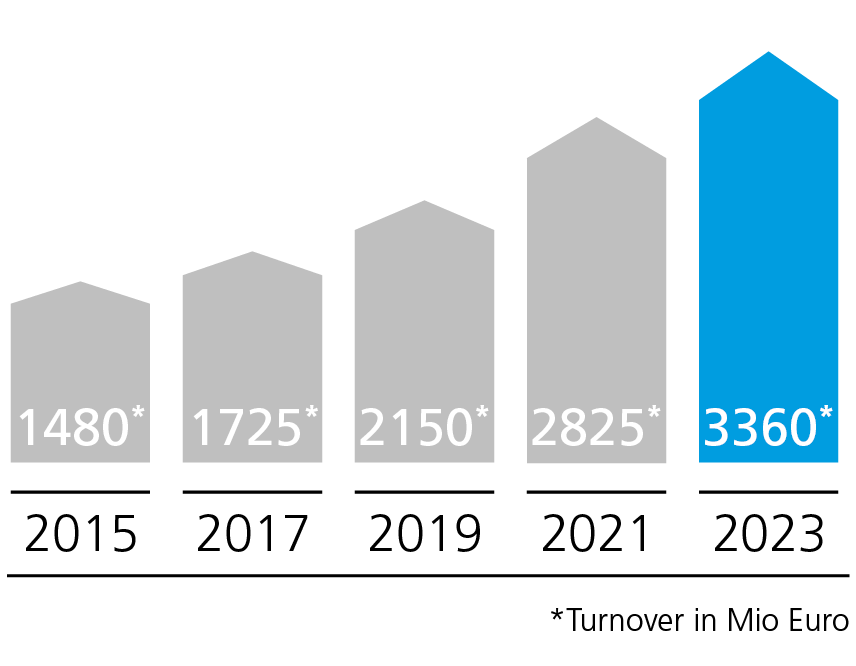

Geisel puts the total investment for all seven elements at around 250 million Euro. "For a supplier of our size, managing this kind of workload in just 24 months is a massive challenge. It is only feasible with a huge effort and unconditional commitment." The CEO of the group of companies is convinced that the commitment will pay off. "In the current year, Boysen will achieve a turnover of one billion Euro for the first time. From 2015, we will see the impact of the contracts for the new plants. By 2016, we will be well on the way towards 1.5 billion Euro turnover."

Geisel has outlined three focus areas for the new development site, which will operate as an independent subsidiary within the group of companies as BIN Boysen Innovationszentrum Nagold GmbH und Co. KG: "Some of the development work for our automotive customers, development work for our entire commercial vehicle business with a focus on trucks, and development work for innovation projects in the environmental and energy technology sector." As examples of the latter, he cites projects such as heat exchangers, thermo-electric generators and combined heating and power plants. "With projects like this, we will give our developers in Nagold the opportunity to push ahead with new ideas and concepts, away from the pressures of day-to-day business."

The innovation centre's four-storey main building is due to be completed in February 2014 and, with 4,100 square metres, will have space for up to 120 new employees, primarily development engineers. "The adjacent testing building will be completed by mid-2015. This will provide 3,100 square metres of state of the art test rig technology, some of which is still in development and I guarantee has never been seen in this form."

When asked why Boysen is splitting its development activities over two sites, Geisel responds: "In recent decades we have spent a huge amount on continuously expanding our development and administration centre in Altensteig. But we have reached the limits. The expansion we need is no longer feasible at that site. And there is no question that we do need the expansion. Currently, the major car manufacturers carry out around 60 percent of their development work in house. Following the current trend, this will be just 45 percent by 2020. For us as a supplier, this means that we can only achieve an increase in turnover by expanding our development activities."

Nagold was chosen partly because of its proximity to the headquarters. "This means that our experts can quickly share their experiences and knowledge at any time." The innovation centre is also part of the "Wolfsberg" industrial and commercial park in Nagold, immediately adjacent to the A81 Stuttgart-Singen motorway. "Finding good engineers is likely to become increasingly difficult. As a result we are offering potential new employees not just a working environment that is exceptional in our industry but also easy access from throughout the Stuttgart region."

Leaving aside the construction project in Nagold, the BIN subsidiary was established in 2012 and has already started work. Substantial office space has been rented in the immediate vicinity, where the first eleven employees have been working since the beginning of this year to lay the foundations for implementing the future strategies discussed.

***

The Boysen Group develops and produces sheet metal manifolds, catalytic converters, diesel particulate filters, silencers and complete exhaust systems for cars, commercial vehicles and off-highway applications. Major customers include the German vehicle manufacturers Audi, BMW, Daimler, Porsche and VW, the English brands Bentley and Rolls Royce and the commercial vehicle manufacturer MAN.

The group of companies currently employs around 2,000 people at twelve domestic and international sites. In addition to the development and administration centre and the production plant in Altensteig, Boysen has production sites in Simmersfeld, Salching and Plauen, and also in France, Egypt, India, China and the USA.

***

In case of any queries, please contact:

Christian Grimm

Marketing Team Leader

BIN Boysen Innovationszentrum Nagold GmbH & Co. KG

Lise-Meitner-Straße 21

72202 Nagold

Tel. 07452/83988-20

Fax 07452/83988-99

E-mail christian.grimm(at)bin.boysen-online.de

Free for publication - please send copy