Boysen is a pioneer

in logistics

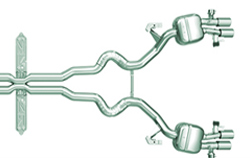

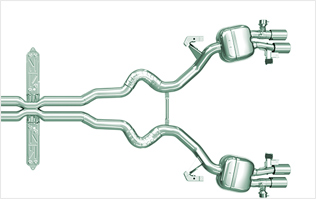

In 1993 Boysen built the world's first local assembly plant for just-in-sequence (JIS) production and delivery of complete exhaust systems at Salching in Lower Bavaria. Since then, we have been continuously optimising this process, enabling us to constantly meet the increasing customer requirements in terms of lead time and number of variations.

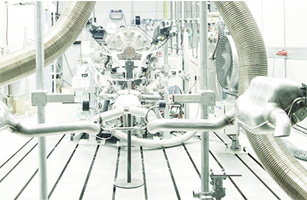

It is based on a production network with sophisticated logistics and an innovative material flow. An integral component of the conveyor technology and thus at the heart of our JIS plants are Boysen's characteristic high bay warehouses. They demonstrate that Boysen is a system partner that gets to the point faster - and gets products onto the conveyor faster.

Logistics milestones

2019

High-bay warehouse with double-deep storage

2018

fully automated tray warehouse for complete exhaust systems

2016

Conveyor technology for one-piece exhaust systems

2014

Five new just-in-sequence production facilities worldwide

2010

New just-in-sequence production structure

2009

Just-in-sequence production for Mercedes Benz Sindelfingen plant

2006

Warehouse on wheels for BMW Leipzig plant

BAK plant / pressing plant logistics systems

2004

Customer-focused sales process

2003

Fully automatic slit strip and tool warehouse

Material flow using electric suspension tracks

2002

Material supply chain management

Material flow simulation

2001

Fractal factory

Material flow integrated into warehouse technology

1993

Just-in-sequence exhaust systems

1991

Online operating data acquisition

1990

Precision control in control room

1989

Material flow technology

Driverless transport systems