Friedrich Boysen GmbH & Co. KG

Turmfeld plant Altensteig

The Boysen Turmfeld plant has been the group's main plant since the early 1970s. The last stage of its expansion in 2011 saw the Boysen vision of a CO2-optimised factory realised at Turmfeld. Electrical power, heating and cooling requirements are largely covered by alternative sources such as solar and geothermal energy.

Start of production

| Turmfeld I | 1972 |

| Turmfeld II | 1988 |

| Turmfeld III | 2011 |

Production area

| Turmfeld I | 7,500 m² |

| Turmfeld II | 10,000 m² |

| Turmfeld III | 17,000 m² |

Facts

| Employees | 480 |

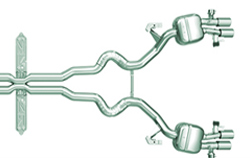

| Services | production of components and complete exhaust systems, production of bent pipes (single and double wall), exhaust trims and exhaust flaps |

| Customers | Mercedes-Benz, BMW, Audi, Porsche, MAN, MTU, AGCO Fendt, Bentley, Rolls-Royce, Boysen Gruppe |

Key features

| CO2-optimised factory |

| certified environmental management according to ISO 14001 and EMAS |

| Certified information security management system in accordance with VDA ISA (TISAX) |

| Exhaust treatment systems for large diesel engines (weighing up to 1.3 tons) |

| Fully automated laser machining centre |

| CNC-controlled bending machines |

| 5-axis laser cutting system |

| Tailored Tubes welding system |

| Welding methods: MAG, WIG, laser |

| 2 Canning systems for car catalytic converters, e.g. gasoline particulate filters (GPF) with single or double-box systems |

| State of the art automatic measuring cell |

| Prototype production of car, commercial vehicle and off-highway applications |

| 10 kW flat-bed laser with diode-pumped disk laser |

| 3 customer-specific hot-end production lines |

| 1 portal welding machine for completion |

Contact

Markus Strebel / Plant Manager

Tel.: +49 (0) 7453 / 20-0

E-mail: friedrich.boysen(at)boysen-online.de

Address / Directions

Friedrich Boysen GmbH & Co. KG

Dieselstraße 1

72213 Altensteig