Altensteig, 4th September 2012 - "The future may at some stage be dominated by purely electric drives", says Rolf Geisel, CEO of Friedrich Boysen GmbH & Co. KG, Altensteig. "But the present indisputably belongs to the combustion engine."

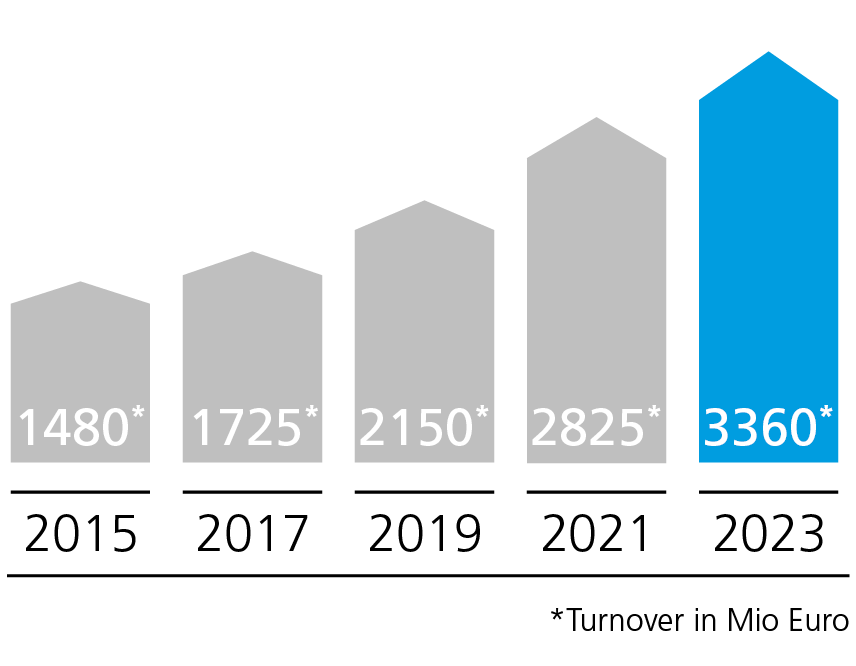

Boysen's success is largely based on increasing global demand for premium cars with efficient petrol or diesel engines. The exhaust technology specialist increased its turnover by 23 percent to 781 million Euro in the 2010 financial year and by a further 24 percent to 969 million Euro in 2011. Back in 2006, the medium-sized foundation company, which has 1350 employees, had a turnover of 480 million Euro. This means that Boysen has more than doubled its turnover within five years and has increased the number of jobs in the group by 40 percent to 1900. The supplier is pursuing more ambitious growth targets for the future: "The Boysen Group's turnover will pass a billion Euro in 2013. In 2015 it will be 1.5 billion", predicts Rolf Geisel.

Geisel expects the main impetus for growth in the coming years to come from exhaust technology for commercial vehicles and off-highway applications. In the new commercial vehicles division, implementation of the stringent Euro 6 emissions standard in 2014 will provide major opportunities. Boysen won the first contract to develop exhaust technology for commercial vehicles from MAN back in 2009. "We are currently building up the required production facilities at our main Turmfeld plant", says Geisel. "Series production will begin at the start of 2013." In 2011, the company also acquired Mercedes Benz commercial vehicles as a new customer.

To date, the exhaust technology specialist has primarily benefited from its customers' sales success with cars. In the automotive sector, Boysen is a system partner to leading manufacturers including Audi, BMW, Daimler and Volkswagen. The luxury marques Bentley, Bugatti, Lamborghini, Porsche and Rolls Royce are also customers. The three German premium manufacturers - Audi, BMW and Mercedes - collectively account for 90 percent of Boysen's turnover. "The numbers vary a little from year to year", says Rolf Geisel, "but generally speaking the volume is evenly split between the three manufacturers." However, Geisel expects turnover with VW to increase in the future.

In the past, Boysen was seen in the industry as a specialist for high-volume powerful engine types. Those days are gone. The company has now established itself firmly in the "mass market for premium cars" (Geisel). "The lion's share of our turnover now comes from high-volume models", says Rolf Geisel. "Specifically the Audi A4, the BMW 3 Series and the Mercedes C Class." This is unlikely to change in the future.

The Boysen CEO believes that the key to their success with all three premium marques is a special production concept. "The costs of transporting bulky items such as exhaust systems and silencers long distances are too high. Instead, we offer our customers components produced in specialist plants in the immediate vicinity of their car factories, assembled into complete systems on a just-in-sequence basis." All the major suppliers in today's market are capable of developing and manufacturing high-performance exhaust technology. This means that the already huge price pressure has actually intensified. "For decades we have deliberately positioned ourselves in the market as a 'partner for development, production and logistics'", says Geisel. "Now that it is increasingly difficult to differentiate by the product itself, we set ourselves apart from the competition by offering a sophisticated production concept." Central to this concept is just-in-sequence production of complete exhaust systems: the company only produces what the customer orders and the systems are delivered directly to the assembly line in the precise order in which they are needed.

Boysen has long been a pioneer in just-in-sequence (JIS) production. In 1993/94 the company constructed the first local assembly plant for JIS production of complete exhaust systems at Salching in Lower Bavaria. "These days, JIS is widely used throughout the industry. However, most of our competitors limit themselves to sequenced deliveries. By contrast, we produce just-in-sequence too." The specialists at Boysen have continuously refined the production principle over time. "Today we have what are essentially standardised factory formats", Rolf Geisel explains. "In our new plants, we produce everything under one roof - from small parts to components through to the complete exhaust system." Above a certain volume, standardised production technology and processes combined with a high level of automation enable exhaust technology in Boysen quality to be produced using the JIS method practically anywhere in the world. Boysen is already using the principle successfully at its Salching, Simmersfeld, Plauen, Shenyang (China) and Gaffney (USA) sites.

"The concept has made a major contribution to us winning various major contracts recently", says Rolf Geisel. The Boysen CEO cites the exhaust technology for Daimler's MRA (Mercedes Rear Architecture) platform as just one example.

According to announcements to date, by the end of 2014 Boysen will open four new production plants just to supply Daimler. Construction work began on schedule in April at Achim near Bremen. The diggers will soon be starting work at Tuscaloosa in the US state of Alabama, East London in South Africa and the Chinese capital, Beijing. A decision on construction of a fifth plant to handle the contract to develop and produce the exhaust technology for the successor to the current Audi A4 has now been made. Boysen will construct a just-in-sequence production facility for complete exhaust systems at its Ingolstadt site, also due for completion in 2014. The new factory will create between 50 and 70 jobs. Meanwhile, Boysen CEO Rolf Geisel is already thinking about building a sixth new plant. However, plans for the Boysen plant in Mexico are still at a very early stage.

In total contrast to the advancing decentralisation of its production, Boysen continues to concentrate its development capacity at its headquarters in Altensteig. The development and administration centre (EVZ) combines design, prototype construction and testing. With the opening of its third testing building in 2010 - an 18 million Euro investment project with a futuristic glass façade - the company installed state of the art test rig technology for testing exhaust systems and components for commercial vehicles and off-highway applications. "With our rapid expansion, we believe that the short distances between individual development departments and between the EVZ and production in the Turmfeld plant are essential for sharing expertise and for pragmatic pursuit of our development objectives", says Rolf Geisel. "Feasibility of series production" for a component has to be established during development, "the sooner the better".

"I am convinced that the focus of our growth for the next 20 years will remain in exhaust technology", says Rolf Geisel. This is plenty of time for Boysen to gear itself up for the age of electric mobility through further diversification of its business activities.

There are currently some indications that the company will become more involved in the energy sector moving forward. "We believe that the issue of energy will become increasingly important - particularly stationary applications, such as domestic systems or building and heating technology", says Geisel. Development of heat exchangers and thermo-electric generators means that Boysen already has a certain amount of experience in the field of energy technology. This is something they can build on. However, of the various concepts and scenarios currently being discussed internally, none is sufficiently advanced to be announced yet.

In November 2010, Boysen took another step towards diversifying its business by acquiring a 14.9 percent stake in the engineer service provider Bertrandt AG. The deal attracted a good deal of attention at the time. Boysen CEO Rolf Geisel now speaks quite calmly about the issue. "At the time, it was debatable how much longer we would be able to achieve the necessary growth rates in the exhaust sector. And we had been looking at Bertrandt for quite some time. So when the opportunity came up, we acquired a shareholding from the LBBW."

Until it took the stake in Bertrandt, Boysen - a conservative medium-sized company - had always invested profits back into the company itself and in further growth. The investment in the engineering service provider was new ground for Boysen. But the assessment that it was a good investment has been completely borne out to date. Because of this, Geisel would definitely be inclined to acquire a further shareholding. "We'd certainly be interested but the focus of our investment is once again on our core business area of exhaust technology."

The experienced businessman has no qualms that Boysen might be over-reaching itself with its ambitious growth plans. "As you know, I've been in this business for a while", says Geisel with typical Swabian modesty. In actual fact, he celebrated 40 years working at Boysen in August. After acquiring his secondary school leaving certificate, Geisel began an apprenticeship as a toolmaker on 1st August, 1972. The 56-year old took on the responsibility of CEO in September 1985.

Geisel leaves open the question of whether he will make it to his 50th anniversary. When asked directly, he replies: "I may not quite make it - at least not right on the front line." It is certainly conceivable that "Mister Boysen" will retain links to the company after his retirement from full-time work by serving for a few years as chairman of the management board.

Boysen develops and produces manifolds, catalytic converters, diesel particulate filters, silencers, trims and complete exhaust systems for cars, commercial vehicles and off-highway applications. In addition to its three main customers Audi, BMW and Daimler, the exhaust technology specialist works for the German car manufacturers Porsche and VW the British manufacturers Bentley and Rolls Royce, the commercial vehicle manufacturers MAN and Daimler, and for Krauss Mafffei, mtu, Voith and others in the off-highway sector.

The group of companies currently employs around 1900 people at ten domestic and international sites. In addition to the development and administration centre and the production plant in Altensteig, Boysen has production sites in Simmersfeld, Salching and Plauen, and also in France, Egypt, India, China and the USA.

***

In case of any queries, please contact:

Martin Stuka

Press and Public Relations

Friedrich Boysen GmbH & Co. KG

Friedrich-Boysen-Straße 14-17

72213 Altensteig

Tel. 07453/20-274

Fax 07453/20-4274

E-mail martin.stuka(at)boysen-online.de

Free for publication - please send copy